Print PDF Version

Print PDF Version

Code BiteSize

Code BiteSize

Copies of pro-formas

Interlock Key Register

Related UKRI code

Contents

Revisions

1

| Initial release

|

| December 2014

|

1.01

| B2.4 Working On and Testing LV equipment

| NP exemption to work on and test equipment and cables rated above 100A

| September 2017

|

Table LV1 and B8.2 Safety Programme

| Safety programme exemption

|

Appendix C.1 Training requirements

| NP Training – courses available

|

Appendix C.1 Training requirements

| AP Training – courses available

|

Appendix C.1 Training requirements

| Asbestos Awareness training

|

Tables LV1, LV2 and LV3

| Equipment with two sources of supply

|

Appendix G Personnel Protective Equipment

| Arc flash protective clothing

|

B9.1 Permit To Work, Tables LV1 & 2

| Street lighting circuits

|

1.1

| Appendix H Document Retention Policy

| Appendix added

| April 2018

|

Appendix G Personal Protective Equipment

| Insulating Gloves

|

1.2

| Changes related to the launch of SHE Assure

| October 2018

|

1.3

| Minor change to title of 4.7

| January 2020

|

2.0

| Major revision of code and Appendices

| November 2024

|

2.3

| Revisions to Appendix B

| May 2025

|

NB - The changes to version 2.0 were considerable and readers should assume that significant portions of the body and Appendices have changed.

1. Purpose

The nature of STFC operations involves the widespread and pervasive use of electricity from low voltage electrical systems found in offices and workshops through to high voltage distribution systems and high voltage scientific equipment.

Electricity (and stored electrical energy) is taken for granted in almost every aspect of our daily lives, but nevertheless has the potential to cause death through electric shock, serious injury through electrical burns; electrical fires (the most common source of fire in the STFC); and damage to equipment and property resulting in lost time and delays to scientific and technical programmes.

Electrical safety is the subject of extensive and detailed legislation and guidance:

- Electricity at Work Regulations, 1989;

- IET Wiring Regulation, latest edition.

- Electricity Safety, Quality and Continuity Regulations, 2002;

- Provision and User of Work Equipment Regulation (PUWER), 1998;

- Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres Regulations, 1996;

- Supply of Machinery (Safety) Regulations, 1992; and

- Electrical Equipment (Safety) Regulations, 1994.

This code outlines STFC policy with respect to the management of electrical safety hazards and the arrangements for complying with the legislation listed above. It sets out the electrical safety rules and procedures throughout STFC Practical implementation of this code may also result in detailed local rules or procedures.

2. Scope

The primary purpose of this code is to define the safety management and practices for those engaged in activities with electrical experimental and/or distribution equipment.

This code applies to all staff, tenants, visitors, facility users and contractors at all STFC sites.

Compliance with this code is mandatory when performing the following functions: specification, design, fabrication, procurement, installation, testing, working on or near, commissioning, operation, modification, maintenance / repair, inspection, and decommissioning of Electrical and Electronic Equipment at all STFC sites.

This code applies where STFC staff undertake electrical work at other sites unless the host site’s arrangements provide equivalent or improved electrical safety control.

This code specifically excludes:

- Electrical installations on STFC sites not under the direct control of the STFC for example incoming substations.

- The safety management within STFC workshops and support laboratories for the fabrication, assembly and testing of electrical equipment.

Due to the pervasive nature of electrical safety hazards there are a large number of related STFC SHE codes and policies, including but not limited to:

3. Definitions

See section 5 for definitions of other items.

3.1. Electrical Distribution System

The Site Electrical Distribution System from point of entry to the Site to the agreed single points of demarcation for experimental electrical systems. Including all high voltage switchgear, step down transformers, ring main units, conductors and all other related electrical equipment used to receive high voltage electricity and to re-distribute it at lower voltages.

3.2. Experimental Electrical System

Electrical systems directly associated with experimental rigs and facilities requiring additional specialist safety procedures. These systems must have an agreed single point of isolation from the Site Electrical Distribution System.

3.3. Electrical Equipment

Electrical equipment becomes part of a permanent (fixed) installation when connected to an electrical system (or a generator), it includes electrical equipment connected by means of a flexible cable, plug and socket, such as handheld or hand operated equipment while connected to the supply. It also includes extension leads that supply electrical equipment and are not part of the fixed installation. See SHE Code 17 Inspection and Testing of Electrical Equipment.

3.4. Point of Demarcation

This is normally a switch, circuit breaker or cable termination on an Electrical Distribution System that has been agreed by the relevant Authorising Engineers as the point of demarcation between the two areas of responsibility. This would normally be identified on a single line diagram as the single point of demarcation.

3.5. Voltage

The following ranges of voltage are defined for non-conductive environments:

- High Voltage: A potential normally exceeding Low Voltage;

- Low Voltage: A potential normally exceeding Extra-Low Voltage but not exceeding 1000 volts ac or 1500 volts dc between conductors, or 600 volts ac or 900 volts dc between a conductor and earth; and

- Extra-Low Voltage: A potential normally not exceeding 50 volts ac, or 120 volts dc, between conductors or between conductor and earth.

The RMS ripple on the dc supply is not to exceed 10% of the nominal dc.

High voltage is regarded internationally as being in excess of 1000 volts ac. However in some UK systems the term `high voltage` is used where the voltage exceeds 650 volts.

Voltages in the Extra-Low Voltage range may still present a considerable hazard and when work is carried out on equipment operating in this voltage range a risk assessment should be carried out.

Particular precautions should be employed on equipment, which exceeds 5 Joules of stored energy and is able to exceed 5mA output current on short circuit or 1.2 cal/cm3 Incident Energy.

3.6. Electrical Live Working

An activity in which a person makes contact with energized parts or encroaches inside the live working zone (BS EN 50110-1) with either parts of their body or with tools, devices or equipment. Electrical Live Working is to be avoided whenever possible. Exceptionally, live working is permitted by an Authorised Person or Nominated Person where a Sanction to Work on or near Live Equipment (see section B11) or Local Rules specific to the equipment to be worked on, have been approved by the Authorising Engineer. All live work must have a risk assessment and method statement specifically written for the activity.

3.7. Electrical and Electronic Equipment (abbr. Equipment)

Anything used, intended to be used or installed for use, to generate, provide, transmit, transform, absorb, rectify, convert, conduct, distribute, control, store, measure or use electrical energy.

3.8. Electrical System

All electrical equipment and connected test equipment that is or may readily be connected electrically to a common source of electrical energy. A system encompasses all the constituent parts e.g. conductors, insulation, protective conductors, insulators and electrical equipment in it, and not simply the functional circuit.

Notes:

- Equipment which may readily be made live by a system is considered part of that system. For example, a lighting circuit disconnected from its source of electrical energy by means of removable links or fuses is still part of that system and so is a circuit which has been switched off even though the switch might be a double pole switch.

- A common source of electrical energy includes systems fed by several generators or transformers.

- In the case of transformers where energy is transmitted over galvanic separation between transformer windings, even though they are not connected electrically, the transformer and all its windings are part of the same system.

- Electrical circuits or equipment whose singular source of supply is batteries are not part of the system (such as test equipment, unless it is connected to the system)

3.9. Authorising Engineer

An engineer whose appointment has been approved by the Director to be responsible for implementing and monitoring this SHE Code.

3.9.1 Coordinating Authorising Engineer (CAE - Electrical)

Where there are more than one Authorising Engineer working within a specific site or campus, one will be formally appointed to coordinate the dialogue between the AEs and the SHE Group. The CAE is responsible for ensuring that there are suitable arrangements in place for the implementation of SHE Codes within their areas of responsibility. The CAE co-ordinate AP functions where required

3.10. Authorised Person (AP - Electrical)

A person who has been appointed in writing by the Authorising Engineer on behalf of the Director to be responsible for the implementation and operation of this SHE Code.

3.10.1 Coordinating Authorised Person (CAP - Electrical)

Where there is more than one Authorised Person appointed for a system or installation, the Authorising Engineer should formally appoint one as a focal point for communication and cascading to other APs. Including activities as an AP, any Authorised Person who is nominated as CAP is in overall charge with responsibility for control of records etc.

3.10.2 Senior Authorised Person (SAP - Electrical)

A specialist or third party appointed person responsible for the planning, design, organisation, control and monitoring all types of construction and maintenance work on LV/HV networks up to 11kV and associated plant and equipment, including complex design, commissioning and fault diagnosis in accordance with safety and customer requirements, ensuring that all works are completed to time and budget. An individual having experience an SAP on utility HV systems, with DNO Operational Authorisation to 11kV OHL & UG with Sanction for Test and have a good knowledge of a wide range of High Voltage plant and equipment.

3.10.3 Duty Authorised Person

An AP who has current responsibility for a system or installation. The AE to define the local working practices of the Duty AP, such as record acceptance of keys and responsibilities as Duty AP in the site Electrical Distribution Operating Record and displayed at the mimic diagram. They will personally hold or carry an Authorised Person’s key(s), normally stored in the system key press. The Duty AP shall relinquish duties in the EDOR as required or on completion of the works.

3.11. Nominated Person

A person certified by an Authorised Person or Authorising Engineer for defined work and with suitable and sufficient technical knowledge and experience to prevent injury, and who has:

- an adequate knowledge of electricity to undertake the defined work activity;

- an adequate experience of electrical work to undertake the defined work activity;

- an understanding of the system to be worked on and practical experience of that class of system;

- an understanding of the hazards which may arise during the work and the precautions which need to be taken;

- the ability to recognise at all times whether it is safe for work to continue; and

- the ability to recognise their own limitations.

A Nominated Person, whether STFC employed or a contractor, can be electrical qualified or non-electrical qualified, the Authorised Person or Authorising Engineer shall assess qualifications, competency and experience before issuing a letter of Appointment.

An Authorised Person can be assessed and appointed as a Nominated Person to receive safety documents or to work under Tables HV1, HV2, LV1, LV2 or LV3.

Operatives working in Hazardous areas (DSEAR/ATEX) shall be able to demonstrate their competence and provide evidence of attaining the knowledge and skill required in BSEN 60079-14 for selection, erection, testing and inspection for the specific area hazards.

3.12. Person in Charge

Person in Charge.

- An Nominated Person who has accepted a Permit to Work, a Sanction to Test, a Sanction for Work on or near Live Electrical Equipment, a Specific Written Instruction or an Authority for Access, for a particular task from another Authorised Person, or

- An Nominated Person who has accepted Standing Instruction from an Authorised Person, or

- An Nominated or Authorised Person who is responsible for working on or testing low voltage equipment in accordance with Table LV3.

3.13. Accompanying Safety Person

A competent person who has received suitable training and has adequate knowledge, experience and the ability to recognise hazards. They are required to keep watch, prevent interruption, summon help and apply first-aid. The person is to have sufficient familiarity with electrical systems being worked on and have received instructions on how to disconnect the equipment from all supplies of electricity, and how to switch off or disconnect any test equipment. They will not be directly involved in the work or involved in anything to distract them from their duties.

4. Responsibilities

4.1 Directors shall:

-

4.1.1 Have overall authority and responsibility for clearly defined electrical systems and electrical network(s)

-

-

4.1.2 Ensure that the specification, design, fabrication, procurement, installation, testing, commissioning, operation, modification, maintenance / repair, inspection and decommissioning of electrical systems are carried out by a sufficient number of competent people and that sufficient resource and facilities are available to implement the requirements of this code.

-

4.1.3 Appoint sufficient and suitably qualified and/or experienced Authorising Engineers for their Department who have successfully completed training, and ensure that their appointment and scope of responsibility are recorded in the

STFC SHE Directory, which will generate appointments in writing (See

Appendix C for training and experience requirements). Where necessary, collaborate with or share such appointments with other Departments.

4.1.3 Appoint sufficient and suitably qualified and/or experienced Electrical Authorising Engineers for their Department who have successfully completed training, and ensure that their appointment and scope of responsibility are recorded in the STFC SHE Directory, which will generate appointments in writing (See

Appendix C for training and experience requirements). Where necessary, collaborate with or share such appointments with other Departments.

-

-

4.1.4 Ensure that the Department hold sufficient electrical safety meetings to justify compliance with this code and report findings to the STFC Electrical Safety Committee and Departmental Safety Committees.

-

-

4.1.5 Discuss with the Authorising Engineer, as a minimum annually, the implementation and performance of the safety rules and review any matters of concerns

4.2

Authorising Engineers shall:

-

4.2.1 Implement, administer, monitor and audit (see Appendix D) the application of this SHE code.

-

-

4.2.2 Ensure their out of hours contact details are available to those responsible for managing site emergencies.

-

-

4.2.3 An Authorising Engineer can undertake the duties of an Authorised Person within their area of appointment and may undertake duties as an Authorised Person in an area under the responsibility of another Authorising Engineer, however their work as an Authorised Person should be audited by another Authorising Engineer.

-

-

4.2.4 Ensure STFC subscribes to a suitable industry forum where serious electrical incidents, equipment faults/failures and manufacturers advisory notices are published. Whenever the forum reports on matters that are relevant to STFC, cascade the information in a timely manner.

-

-

4.2.5 Ensure any electrical appointed person does not exceed a maximum total working day as defined in SC08 Travel on Council Business

-

-

Appointment and management of Authorised Persons

4.2.6 Appoint sufficient Authorised Persons to ensure cover at all times, for all electrical systems, installations, and equipment for which they are responsible. Record the scope of their responsibilities in the

STFC SHE Directory, which will generate appointments in writing. Ensure that Authorised Persons have at the time of appointment the required training and competence, and maintain their training and competence thereafter (see

Appendix C).

4.2.6 Appoint sufficient Authorised Persons to ensure cover at all times, for all electrical systems, installations, and equipment for which they are responsible. Record the scope of their responsibilities in the STFC SHE Directory, which will generate appointments in writing. Ensure that Authorised Persons have at the time of appointment the required training and competence, and maintain their training and competence thereafter (see

Appendix C).

-

4.2.7 Ensure absolute clarity of responsibility for Authorised Persons such that, while there may be more than one Authorised Person appointed for an electrical system, only one is responsible for any defined work or test on an electrical system at any one time.

-

-

4.2.8 Defining in writing, using drawings and diagrams as appropriate, the exact extent of the electrical systems and installations for which each Authorised Person is responsible, keeping appropriate records for each. Clear demarcation must be in place between areas covered by different Authorised Persons.

-

-

4.2.9 Report to their appointing Director any deficiency in the number of suitably trained and experienced Authorised Persons.

-

4.2.10 Review the competence of Authorised Persons at least every 5 years or more frequently depending on performance and if necessary suspend their appointment and remove their names from the

SHE Directory informing the Authorised Person in writing of the reasons why. The Director is to be advised of such action and the corrective action recommended ensuring the continued safe operation of the electrical systems and installations.

4.2.10 Review the competence of Authorised Persons at least every 5 years or more frequently depending on performance and if necessary suspend their appointment and remove their names from the SHE Directory informing the Authorised Person in writing of the reasons why. The Director is to be advised of such action and the corrective action recommended ensuring the continued safe operation of the electrical systems and installations.

-

-

4.2.11 Ensure all Authorised Persons are made aware of any relevant safety information, defect report or operational restriction on the electrical systems or equipment for which they are responsible as soon as is reasonably practicable, providing appropriate advice to prevent injury. (Example NEDeRS – Engineering Directorate).

-

Management of Electrical Systems

-

4.2.12 Ensure that the electrical systems under their responsibility have accurate documentation, including drawings / schematics available, so that the electrical system can be operated and maintained safely. All changes to the electrical system shall be recorded.

-

-

4.2.13 Ensure that all electrical incidents, near misses, hazardous conditions, dangerous occurrences or failures of electrical safe systems of work, under their responsibility, are promptly reported by the relevant Authorised Persons and others undertaking electrical works, including contractors through

Evotix Assure following SHE Code 5 -

Incident Reporting and Investigation.

-

-

4.2.14 Investigate incidents involving electrical systems and installations within their area of appointment. Where learning points can be derived, work with SHE Group to ensure that the learning is cascaded to their Authorised and Nominated Persons and to the wider STFC electrical community.

-

-

4.2.15 Ensure that the correct signage identifying electrical hazards and contact telephone numbers are displayed outside all electrical substations and switch rooms.

-

-

4.2.16 Ensure that a list of significant hazards is displayed in or near all substation areas, switch rooms, switch cupboards, and adjacent to all distribution switchgear which is not confined to a specific room.

-

-

4.2.17 Under normal circumstances STFC does not permit live working on HV or LV systems, see section B11. However, in exceptional circumstances the Authorising Engineer may authorise such work for example, fault finding, testing and commissioning, near HV Experimental Equipment or on / near LV systems, and shall ensure the following criteria are met:

- it is unreasonable in all circumstances for the electrical equipment to be dead and

- it is reasonable in all circumstances for any person to be at work on or near conductors whilst they are live and

- suitable precautions (including where necessary the provision of suitable protective equipment) are taken to prevent injury,and

- the authorisation for live working is documented.

Where live working is considered necessary the Authorising Engineer shall ensure that a documented risk assessment is undertaken before giving written authority for work on or near live electrical equipment. The Authorising Engineer shall ensure that the people undertaking the work are thoroughly familiar with the risk assessment and that an accompanying safety person is appointed.

-

-

4.2.18 Ensure that all amendments to this SHE Code are brought to the attention of all staff and others engaged in work on electrical systems at STFC sites for example Authorised Persons, Nominated Persons, electrical contractors etc.

-

-

4.2.19 Acceptance or otherwise of new works see section B25.

-

-

4.2.20 Ensure that statutory fixed wiring testing of electrical distribution systems is undertaken 5 yearly by suitably qualified persons supported by annual routine monitoring. Records of tests should be retained.

-

-

4.2.21 Authorising Engineers do not have authority to deviate from this Code. Where, exceptionally, they consider that it is appropriate to deviate from the Code temporarily; they must first obtain the agreement of the appropriate Director and SHE Group, and record the details and reasons in writing and complete a risk assessment.

4.3

Authorised Persons shall:

-

4.3.1 Be responsible for the practical implementation and operation of this SHE Code for the equipment for which they have been appointed to install, operate, test, work on or maintain etc.

-

-

4.3.2 Ensure that, where the hazards are significant, a suitable documented risk assessment is undertaken for the work planned, see SHE Code 6, Risk Management.

-

-

4.3.3 On matters related to this SHE Code the Authorised Person’s instructions are mandatory. In the case of a dispute, the Authorised Person is to stop the work or test and refer the matter to the Authorising Engineer for adjudication.

-

-

4.3.4 Ensure all Nominated Persons working within their area of responsibility are made aware of this SHE Code.

-

-

4.3.5 Issue and cancel all documents as described in Appendix A and B relating to the electrical system under their control.

-

-

4.3.6 Withdraw any documents they have issued or that have been issued by another Authorised Person and transferred to them, if the Person in Charge fails to follow the Rules and Procedures set out in this SHE Code, or if an unexpected hazard arises.

-

-

4.3.7 Maintain specialist Personnel Protective Equipment [PPE] (for example face shields, rubber matting, rubber gloves, arc flash protective clothing etc.), Test Equipment and Portable Earthing Equipment for which they are responsible, and ensure the equipment is regularly inspected, calibrated and maintained in good condition, see STFC recommended PPE standards.

-

-

4.3.8 Before any specialist Personal Protective Equipment is used it is inspected prior to use.

-

-

4.3.9 Inform the Authorising Engineer, in writing, of any defects that may compromise safety in an electrical system or equipment.

-

-

4.3.10 Ensure that all electrical incidents, near misses, hazardous conditions, dangerous occurrences or failures of electrical safe systems of work, under their responsibility, are reported as soon as is reasonably practicable through Evotix Assure following SHE Code 5 - Incident Reporting and Investigation by those undertaking electrical works, including contractors.

-

-

4.3.11 Instruct persons required to operate Electrical Equipment under their control in the safe use of that Electrical Equipment, and advise on the hazards arising from improper operation.

-

-

4.3.12 Ensure that cable detection, identification or location work is undertaken prior to excavation or other works on their electrical systems within the geographic area of their responsibility.

-

-

4.3.13 Where an Authorised Person is unsure of the meaning of any part of this Code they should refer the matter to their Authorising Engineer for guidance.

-

-

4.3.14 Perform the duties of a Nominated Person if approved by Authorising Engineer on their letter of appointment

-

-

4.3.15 If there is more than one Authorised Person working on or testing within an area of responsibility, one shall be nominated Duty Authorised Person and be responsible for overseeing activities.

Management of Nominated Persons and Accompanying Safety Persons

-

4.3.16 Appoint in writing sufficient Nominated Persons, and at the discretion of the AE, appoint Accompanying Safety Persons to undertake electrical work within their area of responsibility for a period not exceeding 5 years, ensuring they are suitably trained and experienced prior to appointment, see Appendix C.

-

4.3.17 Ensure that the record of appointments of Nominated Persons is recorded in the

STFC SHE Directory, which will generate appointments in writing, and maintained.

4.3.17 Ensure that the record of appointments of Nominated Persons is recorded in the STFC SHE Directory, which will generate appointments in writing, and maintained.

-

4.3.18 Review the competence of Nominated Persons at least every 3 years or more frequently depending on performance and if necessary suspend their appointment and remove their names from the

SHE Directory, informing the Authorised Engineer in writing of the reasons why. The Authorised Engineer is to be advised of the corrective action recommended to ensure the continued safe operation of the electrical systems and installations.

4.3.18 Review the competence of Nominated Persons at least every 3 years or more frequently depending on performance and if necessary suspend their appointment and remove their names from the SHE Directory, informing the Authorised Engineer in writing of the reasons why. The Authorised Engineer is to be advised of the corrective action recommended to ensure the continued safe operation of the electrical systems and installations.

-

-

4.3.19 As appropriate approve an Nominated Person (STFC staff, contractors or others) for specific tasks by the issue of a Standing Instruction or Specific Written Instruction (see

Appendix C for training requirements).

-

-

4.3.20 Work with any Nominated Person carrying out activities on the system or equipment within their area of responsibility to develop a written Method Statement where the Nominated Person has produced a Risk Assessment for a task which highlights a cause for concern.

-

-

4.3.21 Stop all electrical works where they consider the activities are not in accordance with this or other SHE Codes.

-

-

4.3.22 When electrical work is being undertaken that requires the presence of an Accompanying Safety Person, see section 4.6 and B6, prior to work commencing instruct them how to disconnect the equipment being worked on from all supplies of electricity, and how to switch off any test equipment or disconnect it from the supply.

4.4

Nominated Persons shall:

-

4.4.1 Sign to accept the responsibility to undertake defined electrical work, identified on the letter of appointment, issued by the Authorised Person for a period not exceeding 5 years.

-

-

4.4.2 Work in accordance with this SHE Code and take all measures necessary to prevent injury to themselves or others, and to prevent damage to Equipment.

-

-

4.4.3 Be aware of the extent and limits of the work to be undertaken, their competence, and of any constraints on the sequence or method of working.

-

-

4.4.4 As appropriate undertake a documented risk assessment of work planned, where the hazards are significant see SHE Code 6, Risk Management, excluding live working - see 4.2.15.

-

-

4.4.5 Only work on or test equipment which is listed on their letter of appointment unless covered by Standing Instructions or other Specific Written Instructions.

4.5 Persons in Charge shall:

-

4.5.1 Prior to commencing work ensure a suitable risk assessment and method statement is in place for the work planned, and the controls detailed implemented.

-

-

4.5.2 Be a Nominated Person, Contractor or Authorised Person who is working on or testing equipment in accordance with Table LV3 see appendix A and B, or has accepted a Permit to Work, Sanction to Test, Sanction for Work on or near Live Electrical Equipment, a Specific Written Instruction, a Standing Instruction or Authority for Access from the Authorised Person.

-

-

4.5.3 Follow the Authorised Person’s instructions and work in accordance with this SHE Code, taking all safety measures necessary to prevent injury to themselves or others and to prevent damage to equipment. Instruct the Accompanying Safety Person, if present, in how to disconnect the Equipment being worked on from all supplies of electricity, and how to switch off any test Equipment or disconnect it from the supply.

-

-

4.5.4 Having accepted a Permit or Sanction, undertake / supervise only the specified work or test. Upon completion of this work or test, the Person in Charge then signs off the Clearance section of a Permit or Sanction.

-

-

4.5.5 If the Person in Charge has to temporarily leave the place of work, the work or test is to be suspended, unless local rules apply, and adequate safe systems of work established.

-

-

4.5.6 Report all electrical safety incidents or near misses to the Authorised Person or Authorising Engineer as soon as is practicable, and in

Evotix Assure following SHE Code 5 -

Incident Reporting and Investigation. Where reasonably practicable following an electrical incident, photographs should be taken before any items are disturbed.

4.6 Accompanying Safety Persons shall:

-

4.6.1 Undertake the following duties (see section B6):

- Maintain a watching brief for those undertaking electrical work for hazards, distractions and other sources of interruption; and

- In the event of an incident summon help, make the work area safe, as appropriate disconnecting equipment worked on from all supplies of electricity, and switch off any test equipment or disconnect it from the supply, and apply first-aid if it is safe to do so.

4.7 Managers of electrical systems, including Contract Supervising Officers, shall:

-

4.7.1 Prior to allowing electrical work on their equipment ensure that a risk assessment and method statement for the work planned has been established, see STFC SHE Code 6 Risk Management. As appropriate seeking the advice of STFC Authorising Engineer or Authorised Person.

-

-

4.7.2 Where such work is undertaken by STFC electrical staff or contractors working on their behalf, the competence of all individuals working on or near electrical systems must be approved by an Authorising Engineer or an Authorised Person before undertaking electrical work or tests.

4.8 Staff, tenants, contractors, facility users and visitors shall:

4.9 SHE Group shall:

-

4.9.1 Ensure that electrical SHE incidents are reported to STFC Authorising Engineers to share learning and experience.

5. Technical Definitions

CAT Rating: Overvoltage installation categories have standards from I to IV. The division of a power distribution system into categories is based on the fact that a dangerous high-energy transient such as a lightning strike will be attenuated or dampened as it travels through the impedance of the system. A higher CAT number refers to an electrical environment with higher power available and higher energy transients. Thus, a multimeter designed to a CAT III standard is resistant to much higher energy transients than one designed to CAT II standards. Many test instruments such as oscilloscopes, multimeters, and component testers often have labels near or next to their inputs that indicate CAT rating.

Charged: A conductive part having an electrical potential through connection, capacitance, induction or static.

Competent Person: often referred to as a skilled person is a person judged by an Authorised Person as competent to receive a Permit or Sanction (usually Nominated Person) or an Authority for Access for works in Switch Rooms and Substations for minor electrical work or work that involves other trades. Competent Persons shall have:

- an understanding of the work they are to perform;

- an understanding of electricity and its potential to harm;

- an understanding of the electrical hazards which may arise during the work and the precautions which need to be taken;

- the ability to recognise at all times whether it is safe for work to continue;

- the ability to recognise their own limitations.

Contractor: any external organisation or other body employed by STFC to carry out specific duties on or within STFC property.

Dead: Not electrically 'live'.

Disconnection: Equipment (or a part of an electrical system) that is not connected to any source of electrical energy.

Earthed: Connected to the general mass of earth in such a manner as to ensure at all times an immediate discharge of electrical energy without risk or, as appropriate, injury.

Electrical Installation (abbr. Installation): An assembly of associated Electrical Equipment to fulfil a specific purpose, which forms part of a system.

Hazardous Area: Any location in which there is a risk to health, including areas identified under DSEAR, see SC20 – Hazardous Area Classification and Explosive Atmospheres. The risk may be due to any hazard, such as combustible material, dangerous substances, explosive materials or atmospheres, poisonous substances, electromagnetic radiation, ionising radiation, or strong magnetic fields. Locations of work should also be considered such as confined space or working at height.

High Voltage Enclosure: A location within which a live High Voltage conductor is or may be exposed without the use of a tool or key.

Interlock: A means to prevent switching operations or access that might cause injury, such as paralleling of supplies, or entering enclosures without the supply being isolated.

International Protection (IP): A specification for degrees of protection provided by enclosures, for example IP2X defines an enclosure providing protection against ingress of foreign objects with a diameter of 12.5 mm, and from a finger being inserted and accessing hazardous parts: the X means there is no protection against ingress of water specified.

Isolate: Equipment (or part of an electrical system) which is disconnected and separated by a safe distance (the isolation gap) from all sources of electrical energy in such a way that the disconnection is secure: - i.e. it cannot be re-energised accidentally or inadvertently.

Live: Any apparatus or conductors that are at a voltage by being connected to a source of electricity.

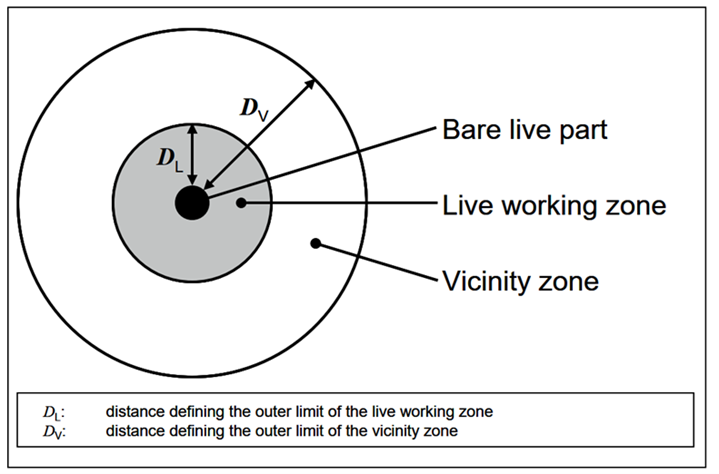

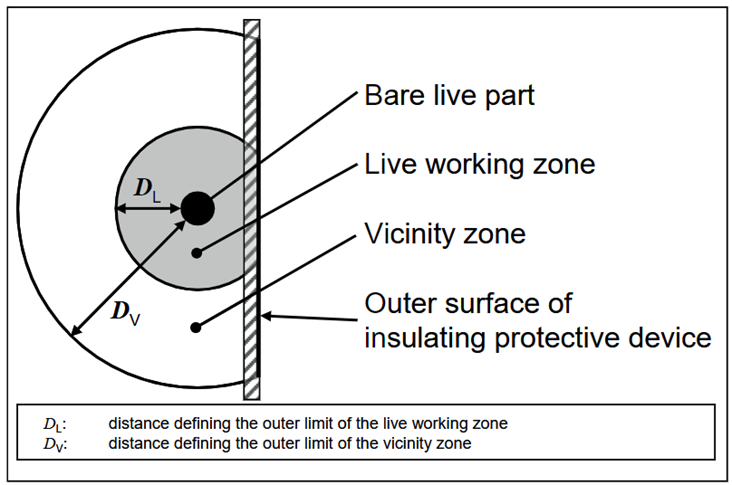

Live working zone: (danger zone BS EN 50110-1) - a space around energized parts where reduction of electrical risk is managed by restricting access to skilled persons only, by maintaining the appropriate air distances to parts at a different electric potential and by using tools for live working: the distance from the energized parts to the outer boundary of a live working zone is greater or equal to the sum of the electrical distance appropriate for the maximum nominal voltage and of the selected ergonomic distance.

Vicinity zone: (working near BS EN50110-1) – a limited space outside the live working zone where specific precautions are taken to avoid encroaching into the live working zone: encroaching into the live working zone will create an electrical hazard from direct contact and electrical discharge.

Distances in air and zones for working procedures:

|

|

Safety key-box (lockout): A safety key-box as a minimum should have two locks, each of which should have only one key: one key should be issued to the Person in Charge receiving the safety document and the other key should be retained by the Duty Authorised Person. It should be so arranged that all locks must be released before access can be gained to the contents of the box.

Mimic Diagram: A single line diagram of an electrical distribution system so constructed that the symbol for each item of switchgear may be adjusted to indicate the ON, the OFF, or the EARTHED position. The symbol for each item of Equipment shall use the appropriate colour identification of voltages to BS EN 60617. These may be digital or physical, however they shall be available at all times.

Protective Conductor (PE): (BS 7671) A conductor used for some measures of protection against electric shock and intended for connecting together any of the following parts:

- exposed-conductive-parts;

- extraneous-conductive –parts;

- the main earthing terminal;

- earth electrode(s);

- the earthed point of the source, or an artificial neutral.

Prove Dead: Demonstrate with an approved two pole voltage detector (GS38) that no electrical potential liable to cause injury is present. Multimeters must not be used for proving dead. Prove Unit or Test supply should meet or exceed the voltage source to be proven dead. Voltage detectors for hazardous areas must be Ex rated.

Proving Unit: see Test Supply.

Removable Temporary Earth: This is an earth, which may be removed for the duration of a test. The Authorised Person lists these on the Sanction to Test, when a Sanction to Test is required.

Substation: Any premises or part of premises in which electrical energy is transformed or converted to or from high voltage, or which contains high voltage switchgear.

Switchboard: High or low voltage switchgear assembled into a single panel or frame.

Switch Cupboard: A room containing distribution boards and other electrical apparatus, but not Distribution Switchgear. An Authority for Access would not normally be required. In exceptional instances where an area classed as a Switch Cupboard may be a shared area, such as those used by cleaners, it may be advantageous to change the reference to show the different level of access control.

Switchgear: An assembly of main and auxiliary electrical equipment for operation, regulation, protection, or other control of an electrical Installation.

Switch Room: A room other than a Substation containing distribution Switchgear. Unless authorised to do so, an Authority for Access would normally be required to enter.

Temporary Earth: A connection to earth made before working on or testing equipment to ensure as far as is practicable that the equipment does not become electrically charged, secured where practicable by a Safety Lock. On completion of a Permit to Work or Sanction to Test these earths are removed by the Authorised Person.

Test Equipment: Equipment to undertake particular tests that is suitable and sufficient for the use for which it is provided, that is maintained in a condition suitable for that use, and that is properly used (see CAT rating definition).

Test Indicator / Potential Indicator: Test Equipment for proving dead and confirming dead in connection with this SHE Code.

Test Supply (or Proving Unit): Test Equipment for proving the function of a voltage Test Indicator or a Potential Indicator for live voltage and phasing Test Equipment or a current Test Indicator.

6. References

- Electricity at Work Regulations, 1989.

- HSE guidance on Regulations HSR25. Memorandum of guidance on the Electricity at Work Regulations 1989.

- Electricity Safety, Quality and Continuity Regulations (ESQCR).

- Guidance on the Electricity Safety, Quality and Continuity Regulations (ESQCR), Department of Trade and Industry.

- BS 7671, Requirements for Electrical Installations, IET Wiring Regulation, latest edition.

- BS EN 61243-3:2010 Voltage indicators, Electrical test equipment for use by electricians, HSE guidance note GS38. (Integral Fuses are prohibited for future purchases of voltage indicators)

- Avoiding danger from underground services. HSE guidance note HSG47.

- Electricity at Work – Safe Working Practices. HSE guidance Information HSG85.

- Keeping electrical switchgear safe, HSG230.

- Electrical Switchgear Safety, General information sheet INDG372 (rev1).

- Safety in Electrical Testing: Switchgear and control gear, engineering information sheet EIS37.

- Safety in Electrical Testing at Work, general Information sheet INDG354.

- Guidance on Safe Isolation Procedures for Low Voltage Installations, HSE and Electrical Safety Council best practice guide no. 2.

- Specification for degrees of protection provided by enclosures (IP code) IEC 60529, as amended.

- Pocket Guide 16, IP codes, NICEIC Pocket Guides.

- Safety in Electrical Testing: Service and repair of audio, TV and computer equipment, engineering information sheet EIS36.

- Using electric storage batteries safely, general information sheet INDG139 (rev1).

- Electrical safety and you, general information sheet INDG231 (rev1).

- BSEN 50110-1 Operation of electrical installations.

- BS 6423 Code of Practice - maintenance of low voltage switchgear.

- BS 6626 Maintenance of switchgear 1kV to 36kV.

- BSEN 60079-14 Explosive atmospheres. Part 14: Electrical installations design, selection and erection.