Print PDF version

Print PDF version

Code BiteSize

Code BiteSize

Related UKRI code

Contents

Revisions

1

| Initial launch | November 2008 |

| 1.1 | Update to BS ENs in References | October 2012 |

| 1.2 | Amendment to audit checklist | May 2013 |

| 1.3 | Minor change to para 4.2.1

| February 2014 |

1.4

| Add Document retention policy

| August 2014

|

1.5

| Changes to responsibilities and action volumes

| January 2015

|

1.6

| Changes to reflect updating of DSEAR legislation, approved codes of practice, and relevant standards.

| March 2018

|

1.7

| Update to reflect the launch of SHE Assure

| October 2018

|

2.0

| Major update to reflect current practice and legislation

| June 2024

|

NB - The changes to version 2.0 were considerable and readers should assume that significant portions of the body and Appendices have changed.

1. Purpose

Dangerous substances can be found in nearly all workplaces and include such things as solvents, paints, flammable gases, dusts from machining and sanding operations.

The Dangerous Substances and Explosive Atmospheres Regulations (2002 as amended) (DSEAR) require employers to assess the risks of fires and explosions that may be caused by dangerous substances in the workplace and then eliminate or reduce these risks as far as is reasonably practicable. The Regulations clarify the existing requirements to manage fire and explosion risks which are set out in the Management of Health and Safety at Work Regulations 1999.

DSEAR deals with the immediate danger to life or health from fires or explosions resulting from the ignition of dangerous substances and eliminate or reduce these risks as far as reasonably practicable. DSEAR must not be confused with COSHH which deals with the chronic and acute health effects Gases that are under pressure (e.g. gas in a cylinder) may present a risk of explosion if not correctly handled in the workplace. Substances that can corrode metals could cause structural damage reducing integrity of structures if not suitably contained. From June 2015, DSEAR places a formal requirement to assess the risks for substances if classified for these properties and put in place suitable control and mitigation measures. The need to carry out a risk assessment and have in place procedures for the safe use of chemicals previously not covered by DSEAR are already required by the general requirements of the Health and Safety at Work etc. Act 1974 and the Management of Health and Safety at Work Regulations 1999. STFC are already managing these duties within the STFC Safety Code framework and so are not considered further within this code.

2. Scope

The application of DSEAR in the technically complex and unique environments that exist within the STFC is beyond the capability of this code to address in full. This code does not endeavour to describe how the risks from all dangerous substances and explosive atmospheres hazards should be controlled, rather it establishes a framework upon which to carry out simple assessments or to be aware of when to involve a external consultant to carry out zoning studies for hazardous area classification (HAC). For technically complex environments the advice of competent experts is required and must be engaged in a timely manner.

The requirements of this code apply to all STFC staff, tenants, facility users and visitors and apply in any instance where dangerous substances are present, used or produced.

The requirements of this code applies to facility user / visitor equipment and experiments and they must be made aware of the code requirements.

The responsibility to undertake a risk assessment for contractor activities lies with the contractor’s management, but it is the STFC responsibility to ensure that risk assessments are in place and the potential hazards are fully understood before work commences. All relevant information to enable the risk assessment to be undertaken by the contractor’s management must be provided. It is also the responsibility of STFC to share any Hazardous Area Classification (HAC) zone maps with the contractor and to highlight any specific safety requirements.

This code does not address other hazardous properties associated with flammable substances. For example toxic hazards are addressed under COSHH, radiation hazards (e.g. tritium), are addressed in relevant radiation management SHE codes and by advice from SHE Group. These additional hazards should be assessed separately. Specific guidance in the handling and use of hydrogen and deuterium can be obtained by contacting the SHE Group.

Also, the use of dangerous substances in confined spaces may create further hazards. This code does not address the hazards arising from confined spaces, see STFC SHE Code 11 Work in Confined Spaces.

3. Definitions

3.1 DSEAR

Dangerous Substances and Explosive Atmospheres Regulations 2002. These regulations apply in any workplace where dangerous substances are present, used or produced, with some minor exceptions (refer to Appendix 1).

3.2 ATEX

ATEX is the name commonly given to the framework for controlling explosive atmospheres and the standards of equipment and protective systems used in them. It is based on the requirements of two European Directives from which DSEAR is derived, and which are described in more detail in Appendix 1.

3.3 EPS regulations

Equipment and Protective Systems intended for Use in Potentially Explosive Atmospheres Regulations 1996 (as amended) (EPA), which came fully into force on 30th June 2003. These regulations cover both electrical and non-electrical equipment and states that any responsible person who places equipment on the market or places equipment into service, must ensure that the essential health and safety requirements have been satisfied.

3.4 Dangerous substances

Any substances that could, if not properly controlled, cause harm to people as a result of a fire, explosion or similar energetic event. A more detailed definition is available in Appendix 1.

3.5 Risk assessment

A process whereby the explosion (or flammable) hazards in a particular area or of a particular activity, arising from the presence, use or production of dangerous substances, are identified and the level of fire / explosion risk estimated taking account of the effectiveness of current control measures in place. See Safety Code 06 - Risk Management.

3.6 Hazard Areas Classification (HAC)

“Hazardous Areas” in DSEAR are “any place in which an explosive atmosphere may occur in quantities such as to require special precautions to protect the safety of workers”. Consequently Hazardous Area Classification is the process of assessing:

- the likelihood that an explosive atmosphere will exist;

- how voluminous it will be; and

- how long the atmosphere could exist for (time) given variables such as ventilation, rate of material production/leakage etc.

For gases and vapours the assessment process will classify the area into one of three zones:

- Zone 0: An area in which an explosive gas atmosphere is present continuously or for long periods;

- Zone 1: An area in which an explosive gas atmosphere is likely to occur in normal operation;

- Zone 2: An area in which an explosive gas atmosphere is not likely to occur in normal operation and, if it occurs, will only exist for a short time.

For dusts and powders the assessment process will classify the area into one of three zones:

- Zone 20: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is present continuously or for long periods or frequently;

- Zone 21: A place in which an explosive atmosphere in the form of a cloud of combustible dust in air is likely to occur in normal operation occasionally;

- Zone 22 – a place in which an explosive atmosphere in the form of a cloud of combustible dust in air is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Additionally, thin layers (i.e. 1mm) of combustible dust can be roused to flammable concentration. Therefore, dust layers in the workplace are likely to be classified as Zone 22.

3.7 Explosive atmosphere

In DSEAR, an explosive atmosphere is defined as a mixture of dangerous substances with air, under atmospheric conditions, in the form of gases, vapours, mist or dust in which, after ignition has occurred, combustion spreads to the entire unburned mixture.

Atmospheric conditions are commonly referred to as ambient temperatures and pressures. That is to say temperatures of –20°C to 40°C and pressures of 0.8 to 1.1 bar.

Note this definition is used synonymously with "Flammable Atmosphere" (i.e. in these regulations they mean the same thing).

3.8 Pyrophoric materials

Pyrophoric materials (includes chemicals and gas) also fall under DSEAR as they have the ability to spontaneously ignite in air which have the potential to result in a fire and /or explosion. Also see related SHE Codes for COSHH SC37 and SC33 Pressure and Vacuum systems.

3.8.1 – Pyrophoric liquids and solids are liquids or solids that even in small quantities, are liable to ignite within 5 minutes after coming into air.

3.8.2 – Pyrophoric gas is a flammable gas that is able to ignite spontaneously in air at a temperature of 54°C or below.

3.9 Explosive limits

Lower explosive limit (LEL): The concentration of flammable gas or vapour in air, below which the gas atmosphere is not explosive.

Upper explosive limit (UEL): The concentration if flammable gas or vapour in air, above which the gas atmosphere is not explosive.

3.10 Flammable Liquid

A liquid as defined for highly flammable liquid (see 3.1.2) but with a flashpoint up to 55°C

3.1.1 Flashpoint The lowest liquid temperatures at which, under certain standardised conditions, a liquid gives off vapours in a quantity such as to be capable of forming an ignitable vapour/air mixture.

3.1.2 Highly Flammable Highly flammable liquid means any liquid, liquid solution, emulsion or suspension other than liquid ammonia, liquified flammable gas and liquified petroleum gas which:a) has a flash point of less than 32°C; and b) when tested, with a heating time of 60 seconds supports combustion

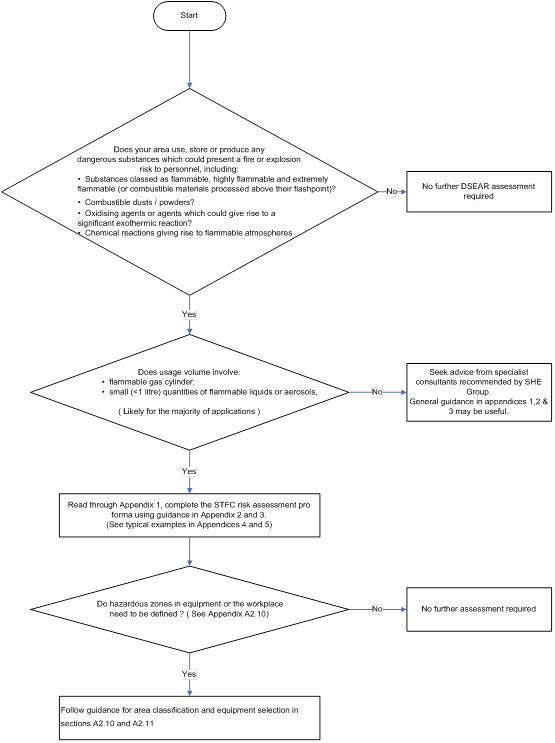

Summary Flowchart.

(click on image to download/view PDF version)

4. Responsibilities

The majority of operations for which fire and explosion hazards exist within the STFC sites are relatively simple, mainly incorporating the use of flammable gas cylinders, laboratory style solvents and covering ancillary areas. Detailed guidance for these types of areas is provided in Appendix 1 and 4 For more complex operations that may entail extensive hazardous areas inside and outside of equipment or where unusual chemical reactions take place, this code does not give specific guidance. In these instances external / professional advice and assistance will be required in undertaking the risk assessment. The format and information in Appendices 1, 2 and 4 will act as a guide

4.1 Group Leaders shall:

-

4.1.1 Ensure all dangerous substances which are to be introduced or are present or are liable to be present in the workplace; the work activities involving them; how they may fail and cause fire, explosion and similar events are risk assessed see STFC SHE Code 6, Risk Management

-

-

4.1.2 Determine whether any activities within their responsibility involve cylinders of flammable gases, or small (<2.5 litre) quantities of highly/extremely flammable liquids or aerosols. Activities outside of these criteria should be referred to SHE Group and advice should be sought from a competent external consultant to undertake the Risk Assessment. This can be arranged through the SHE Group.

-

-

4.1.3 Decide whether their staff are competent to carry out a risk assessment in areas where fire and explosion hazards exist and if not get them trained see Training Appendix 7, or seek external advice via SHE Group.

-

-

4.1.4 Ensure that where risk assessments relating to the use of dangerous substances identify specific actions to control hazards they are undertaken promptly and to plan prior to carrying out the activity.

-

-

4.1.5 Monitor the risk assessments in order to ensure that the controls measures detailed in Risk Assessments are implemented effectively.

-

-

4.1.6 Inform SHE Group so that respective Fire Risk Assessments can be updated.

4.2 Supervisors and Line Managers shall:

-

4.2.1 Carry out risk assessments for all activities (including maintenance activities) and equipment, existing and planned, involving dangerous substances, see SHE Code 6, Risk Management, as appropriate seeking competant external advice, see 4.1.2. Detailed guidance on carrying out risk assessments for activities in which fire and explosion hazards exist can be found in Appendices 2 and 3. Example Risk Assessments for the hazards arising from explosive atmospheres in a typical research environment can be found in Appendices 4 and 5.

However, the assessment should take account of the following:

-

- The hazardous properties of the substances;

- The way in which they are used or stored;

- The possibility of hazardous explosive atmospheres occurring;

- All potential sources of ignition;

- The current controls, both preventive and mitigating, and their effectiveness; and

- Who might be harmed and the potential consequences (i.e. address contact burns, intoxication, asphyxiation and overpressure injuries).

-

- As part of the risk assessment process, IF REQUIRED an Hazardous Area Classification exercise should be carried out for the area where the activity is to take place. The HAC should be documented and appropriate plan and elevation drawings produced to show the extent of the hazardous area. Drawings are not required for NON_HAZARDOUS areas with respect to DSEAR.

-

-

4.2.2 Ensure that equipment located within a hazardous area is fit for that area, see Appendix 2, section A2.11.

-

-

4.2.3 Ensure that emergency arrangements, consistent with the risk assessment and appropriate to the nature of the activity or operation are put in place.

-

-

4.2.4 Report any incidents or near misses relating to dangerous substances to the SHE Group in accordance with SHE Code 5 Incident Reporting and Investigation.

-

-

4.2.5 Contract supervising officers shall ensure that all relevant information to enable the assessment to be undertaken by the contractor's management is provided, see STFC SHE Code 15 Management of Contractors (Section 4.3).

4.3 Staff, users, tenants, contractors, visitors shall:

-

4.3.1 Assist as appropriate in the undertaking of DSEAR assessments by their line manager/supervisor and follow the instructions and control measures determined by these assessments.

-

-

4.3.2 Under Regulation 11 of DSEAR (Duty of Coordination) within shared workplaces effective coordination and communication is required. Shared workplaces might include two or more employers or departments sharing a building.

Employers might take the form of STFC staff, tenants, contractors (term and fixed term), visiting scientists and users etc.

It is the duty of the employer responsible for the workplace or the work that is creating the explosive atmosphere to obtain sufficient information from all employers at the workplace about their nature of work and whether any dangerous substances are likely to be present, and the likelihood of an explosive atmosphere occurring. All employers at the workplace will share any information required and assist in assessing shared risks and implementing any mitigation measures. Coordination and communication is to:

- Alert other employers, employees and others within the workplace to the presence of hazardous places or substances used by another employer.

- Ensure that suitable control and mitigation measures are in place.

- Facilitate emergency arrangements in the event of an incident.

4.4 SHE Group shall:

-

4.4.1 Ensure the implications of the hazards arising from flammable atmospheres are considered in Fire Risk Assessments.

-

-

4.4.2 Provide advice on DSEAR related queries and ensure involvement in any HAC.

4.5 Electrical and Mechanical Engineers shall:

-

4.5.1 Attend a suitable CompEX course (see Appendix 7) and maintain the relevant qualification obtained.

-

-

4.5.2 Ensure that equipment located within a hazardous area is fit for that area.

-

-

4.5.3 Report back to the user/line manager/SHE Group on any defects found in the area.

-

-

4.5.4 Maintain an asset register of all ATEX relevant equipment.

-

-

4.5.5 Advise when required on the safe selection, installation, maintenance, inspection and repair of any equipment.

For additional responsibilities with regard to electrical engineers please see SC34